Additive Manufacturing: The Production Revolution

August 11, 2016

Life can be full of unexpected surprises, including some that contain the potential to disrupt one’s usual routine. Such inconveniences, like a faulty airplane or automobile part, can require extensive time and funds to correct. But what if a defective car part could be fixed without all the hassle?

Life can be full of unexpected surprises, including some that contain the potential to disrupt one’s usual routine. Such inconveniences, like a faulty airplane or automobile part, can require extensive time and funds to correct. But what if a defective car part could be fixed without all the hassle?

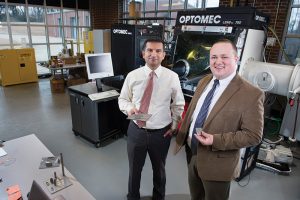

Nima Shamsaei, an assistant professor of mechanical engineering, is working with a team of researchers at Mississippi State to develop a new type of manufacturing process with the potential to save both time and money when life does throw a curveball.

Shamsaei’s academic background focuses on the fatigue and fracture mechanics found in elements of everyday items. Through his research and industry experience at Chrysler, he has learned the importance of studying microstructure in components that experience heavy usage.

“Up to 90 percent of all mechanical failures are a result of fatigue,” Shamsaei said. “Now, I can use my knowledge of fatigue and fracture to determine if additive manufacturing is as good as traditional manufacturing.”

The process of additive manufacturing enlists a 3-D printer to immediately produce a model of a part, printing it layer by layer. Although the method’s complete capabilities are still unknown, Shamsaei has learned that it is capable of fabricating complex geometries and new alloys.

So far, the benefits discovered by the team make additive manufacturing seem like a viable solution to issues that traditional manufacturers have struggled with for centuries.

“Additive manufacturing can be applied to many things,” Shamsaei said. “The biggest benefit is reducing the time between design and production, which can save a lot of money.”

Speed and cost are not the only two benefits on the minds of additive manufacturing supporters. The innovative process would also create jobs and potentially boost the economy by bringing advanced manufacturing opportunities back to the United States.

Shamsaei’s work in fatigue and fracture mechanics is only one piece to the complete additive manufacturing puzzle. Linkan Bian, an MSU assistant professor of industrial engineering, is working to lessen the possibility of failure by minimizing uncertainty. Scott Thompson, an MSU assistant professor of mechanical engineering, is studying how heat from a laser can be manipulated to create a specialized microstructure that withstands heavy usage.

As they continue their research, the question on each MSU team member’s mind is, “Can a part produced by additive manufacturing last as long as the traditionally manufactured part?”

Once this question is answered and other concerns have been addressed, the researchers plan to create software using the generated information and data. During the design phase, they will ultimately use the software to predict the behavior of the part, helping manufacturers avoid potential failure. To use the software, a user will enter data, such as size or application, and will then receive an accurate prediction of how successful the part will be.

“This is about five to 10 years of research and testing. We’ll need a lot of data with different materials and different scenarios,” Shamsaei said. “It’s a lot of work. But it’s worth it.”

Currently, the research is funded through the three assistant professors’ start-up funding and MSU’s Center for Advanced Vehicular Systems (CAVS). They have received additional funding from the National Science Foundation, Army Research Laboratory, NASA and other large industry partners. The group recently were able to obtain membership in the national consortium, America Makes, to earn additional funding and recognition.

“We are very excited about additive manufacturing, and I think we have been able to get some people excited around here, so we are gaining support from the university,” Shamsei said. “We are very hopeful that we can attract more people to support us as we move forward in our research.”

Bagley College of Engineering is online at bagley.msstate.edu.

By: Amanda Meeler